Suspension arm bushings are crucial for vehicle movement, absorbing shock and reducing friction. High-quality, corrosion-resistant materials and installation methods extend bushing lifespan. Modern bushings with advanced polymers and coatings offer superior protection against moisture, salt, and harsh weather, ensuring reliable performance in critical systems like brakes and intake components.

“Discover the essential role of suspension arm bushings in automotive systems and their impact on vehicle performance. This article explores how these components, often overlooked, play a critical part in ensuring smooth rides and safe handling. We delve into the science behind suspension arm bushings, uncovering their benefits and advanced materials that offer superior corrosion resistance. By understanding common corrosion causes, you’ll gain insights to maintain optimal vehicle health.”

- Understanding Suspension Arm Bushings: Their Role and Benefits

- Common Causes of Corrosion in Bushings and Prevention Strategies

- Advanced Materials: Enhancing Corrosion Resistance in Modern Bushings

Understanding Suspension Arm Bushings: Their Role and Benefits

Suspension arm bushings are critical components that facilitate smooth and efficient vehicle movement. They act as bearings, absorbing shock and allowing suspension arms to move freely without excessive wear or friction. These bushings play a pivotal role in maintaining optimal vehicle performance by ensuring a seamless connection between the vehicle’s chassis and wheels.

Beyond their functional benefits, high-quality suspension arm bushings offer superior corrosion resistance, a feature that is particularly crucial for vehicles exposed to varying weather conditions. This durability not only prolongs the lifespan of intake components but also contributes to overall vehicle reliability. By safeguarding against rust and corrosion, these bushings ensure that your vehicle’s suspension system remains in peak condition, enhancing both safety and performance.

Common Causes of Corrosion in Bushings and Prevention Strategies

Corrosion is a significant issue with suspension arm bushings, often leading to reduced performance and increased maintenance. Common causes include exposure to harsh weather conditions, chemical corrosives, and high moisture levels. These factors can accelerate rust formation, compromising the integrity of the bushing over time.

Prevention strategies are essential for maintaining the superior corrosion resistance of these components. Using high-quality materials that are treated for corrosion resistance is key. Additionally, proper installation techniques, such as ensuring adequate drainage and using protective coatings, play a vital role. Regular inspection and maintenance, including cleaning and re-lubrication, can also extend the lifespan of suspension arm bushings. Moreover, investing in performance exhaust systems or suspension kits with built-in corrosion protection features can offer long-term benefits, especially when combined with high-quality muffler tips designed to withstand corrosive elements.

Advanced Materials: Enhancing Corrosion Resistance in Modern Bushings

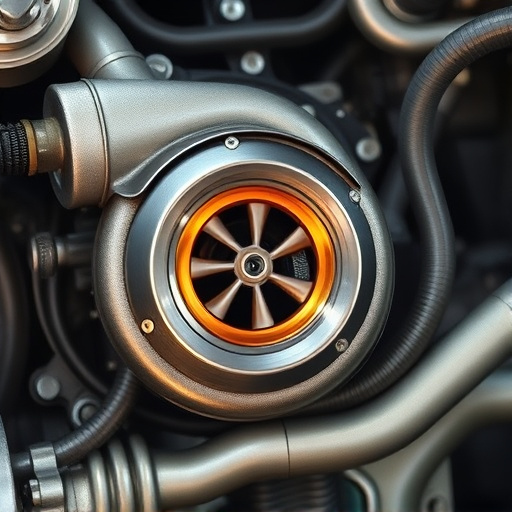

Modern suspension arm bushings are designed with advanced materials that significantly enhance their corrosion resistance. Traditional bushings often suffered from rust and degradation over time, leading to poor vehicle performance and increased maintenance costs. However, new formulations incorporate specialized polymers and additives that not only withstand corrosive environments but also offer superior durability. These innovative materials can effectively protect against moisture, salt, and other elements commonly found in harsh weather conditions, ensuring the longevity of the bushings.

Additionally, the integration of corrosion-inhibiting coatings further strengthens the resistance of these bushings. These protective layers act as a barrier, preventing metal-to-metal contact and minimizing the risk of oxidative damage. This focus on material science has revolutionized suspension arm bushings, making them more reliable components that contribute to enhanced vehicle performance and better overall efficiency, especially when considering critical systems like brakes and intake components.

Suspension arm bushings, key components in vehicle engineering, play a vital role in ensuring smooth rides and enhancing safety. By understanding their function and implementing effective corrosion prevention strategies, manufacturers can significantly prolong the lifespan of these parts. Advanced materials, such as enhanced polymers and stainless steel, offer superior corrosion resistance, providing long-lasting performance even in challenging environmental conditions. This article has explored the importance of bushings, identified common corrosion causes, and highlighted modern solutions, ultimately emphasizing the need for high-quality, durable suspension arm bushings.